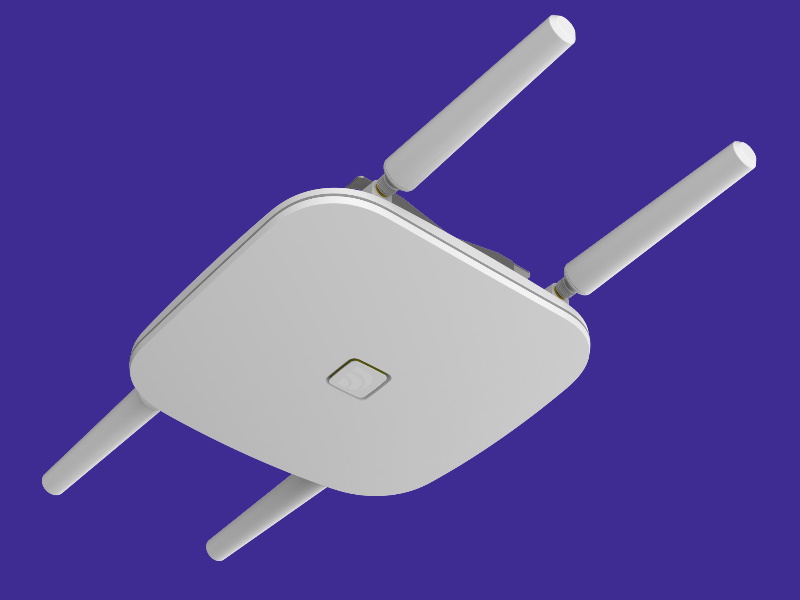

As the only Hardware engineer on the networking team, My time was spent working with cross-functional teams, developing the next generations of hardware, and ensuring all of our devices were specified, designed, to perform at the highest level, while remaining up to regulatory and compliance requirements and performing for years in a variety of environments. I lead the design, validation and verification of the integrated cellular failover routers, the DNA and D200. I was the responsible party for getting our routers end device certified with various carriers, as well as with regulatory and industrial standards bodies. I work closely with the software development teams to ensure our whole platform of cloud-managed, indoor+outdoor global access points that are able to adhere to localize RF limitations and meet all regulatory requirements. As well as with the lower level engineering team in the board bring up of new devices and integration of cellular modules and managed cellular plans provided by datto. I review returned and failed units for analysis and work with manufacturers and ODMs on root cause analysis and modifying designs in order to prevent failures. I worked very closely with the Product Management team, in order to get as close to their desired product functionality as possible, while remaining compliant or finding a different architecture to achieve the desired outcome. I was the responsible team member for organizing a standard practice and organization of new product introduction and maintaining documentation for the product release and post-release. I Defined test strategies for ensuring RF and Hardware Safety compliance, as well as Cellular performance. I reviewed all reports and filings for Datto Networking Products for FCC,ISED, ACMA, IMDA, UL, ETC, CB, etc. to ensure our products were properly reflected for their expected behavior in the field on Open Source software.